Understanding Silicon Carbide Powder

Silicon carbide (SiC) powder stands out as an industrial abrasive due to its exceptional properties. Renowned for a hardness that comes second only to diamond, silicon carbide powder offers superior abrasive qualities, making it the go-to choice for many applications. Its thermal conductivity, resistance to thermal shock and low thermal expansion make SiC powder and silicon carbide discs uniquely suited for tasks requiring precision and durability.

From cutting-edge aerospace engineering to materials science research, this powder facilitates processes that demand the highest levels of performance and reliability. Its ability to deliver a flawless surface finish and its longevity ensures that industries relying on exacting standards favor silicon carbide powders for their critical applications.

Applications of Silicon Carbide Powders in Industries

Silicon carbide powders and silicon carbide discs are critical in enhancing performance and efficiency across various sectors. Their exceptional hardness and abrasive qualities are invaluable for achieving precise finishes and superior cutting capabilities. Here's a closer look at how these materials benefit specific industries:

- Aerospace: In the aerospace industry, SiC powder is essential for manufacturing engine components that withstand extreme temperatures and resist thermal shock. It's also used in thermal protection systems for spacecraft, offering unmatched durability and heat resistance, supporting the safety and reliability of aerospace missions.

- Semiconductor: The semiconductor sector relies on silicon carbide powder for wafer processing equipment, where its thermal properties facilitate efficient heat dissipation. This is critical in producing electronic devices, where managing heat is crucial to maintaining performance and longevity.

- Materials Science: Researchers in materials science use silicon carbide powders to develop advanced ceramics and composite materials. Its hardness and resistance to wear make it an ideal component in creating materials that push the boundaries of durability and thermal stability.

- Energy: In the energy sector, SiC powder is used in components for solar panels and fuel cells, where its ability to conduct electricity while withstanding high temperatures improves the efficiency and lifespan of these renewable energy technologies.

- Medical: The medical industry benefits from using silicon carbide discs to produce surgical instruments and prosthetic devices. The material's hardness and precision in cutting enable the creation of tools and components that meet the highest standards of hygiene and performance.

- Universities: Utilized for cutting-edge research and development, silicon carbide powders aid in exploring new materials and technologies. Their use in academic settings fosters innovation, contributing significantly to the advancement of science and engineering.

- Laboratories: In laboratory environments, silicon carbide discs and powders are indispensable for high-precision analytical work, testing and experimentation, offering reliability and accuracy in results.

- Government Agencies: Governmental projects and research initiatives often employ silicon carbide powder to improve the performance and durability of technologies in defense, energy and environmental monitoring, leveraging their superior properties for national benefit and security.

Frequently Asked Questions About Silicon Carbide Powder

Here, we address some of the most commonly asked questions about silicon carbide powder.

What Are the Benefits of Using SiC Powder in Industrial Applications?

Silicon carbide powders offer exceptional hardness and thermal conductivity, making them the ideal solution for applications requiring high endurance and efficiency, such as abrasive machining and thermal management in electronics.

How Should SiC Powder Be Stored and Handled?

SiC powder should be stored in a cool, dry place, away from direct sunlight exposure and from moisture. Handling should be done with care, using personal protective equipment to avoid inhaling the powder or coming into contact with skin and eyes. Disposal should comply with local environmental regulations. For specific instructions, it's advisable to contact your state's Department of Environmental Protection (DEP) or your local EPA (Environmental Protection Agency).

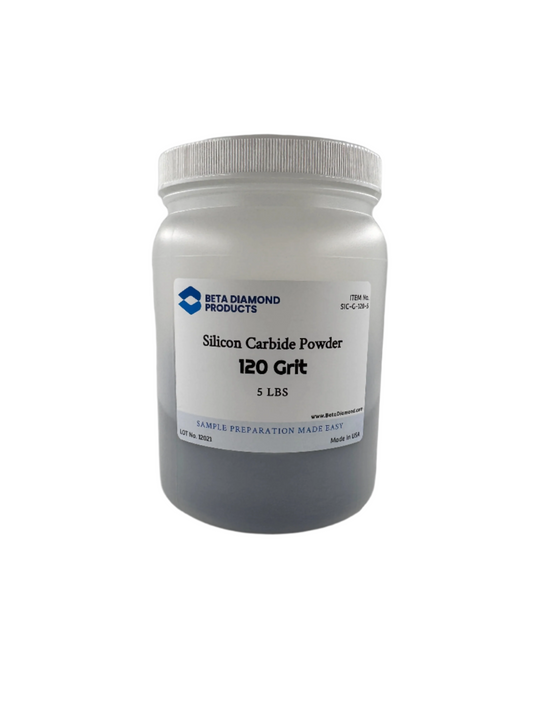

What Makes Beta Diamond's SiC Powder Different From Others on the Market?

Our SiC powder is produced with over 37 years of experience, ensuring unparalleled quality and consistency. We also offer several customization options to suit various industrial applications.

Rely on Silicon Carbide Powder From Beta Diamond Products

Choosing silicon carbide powder from Beta Diamond Products means selecting a level of quality and expertise unmatched in the industry. Our silicon carbide powders and silicon carbide discs are engineered to meet the demands of various high-tech industries. We've perfected the production of SiC powder to ensure maximum performance and reliability. Our long-standing reputation as a trusted supplier is a testament to our commitment to delivering only the best for our clients. Get in touch today, and we'll get your SiC powder to you ASAP!

Shop Now