The Science Behind Alumina Powder

Aluminum oxide (alumina) powder is a versatile and crucial material in various industries, known for its hardness and chemical inertness. This fine, white powder is primarily used as an abrasive in applications ranging from grinding and polishing to surface preparation. With a high melting point and resistance to chemical attack, aluminum oxide power is invaluable in environments where extreme conditions are the norm. In industries like metallurgy, ceramics and refractory, it plays a pivotal role, providing both durability and efficiency. Its unique properties enable it to stand up to demanding applications, making it a go-to choice for professionals seeking reliability and performance.

Using Aluminum Oxide Abrasive in Industrial Applications

Aluminum oxide abrasive stands out for its exceptional qualities. Used in a spectrum of sectors, including laboratory settings, aerospace, semiconductor technology and medical equipment manufacturing, this abrasive offers unparalleled benefits.

Enhanced Durability and Longevity in Harsh Environments

Aluminum oxide abrasives are highly resistant to wear and tear, so they're ideal for use in environments where materials are exposed to extreme stress, such as in the mining and construction industries. This resilience ensures a longer lifespan for tools and equipment, reducing the frequency of replacements.

Superior Grinding Performance Due to Extreme Hardness

As one of the hardest materials available, aluminum oxide abrasive excels in grinding operations. It can efficiently cut through hard metals, ceramics and glass, offering precision and smooth finishes crucial in aerospace and automotive industries.

Resistance to High Temperatures

Aluminum oxide maintains its structural integrity even at temperatures reaching nearly 2,000°C. This makes it particularly useful in manufacturing furnace linings, kiln furniture and thermal barriers in high-temperature processes such as metal smelting.

Minimal Contamination Risk

The chemical inertness of aluminum oxide minimizes the risk of contamination, which is vital in producing semiconductors and medical equipment. This ensures the purity of products, maintaining high quality and safety standards.

Cost-Effectiveness

The durability of aluminum oxide powders means less frequent replacements, which leads to cost savings over time. In addition, its effectiveness in material removal reduces labor costs and increases productivity.

Versatility in Various Applications

From precision polishing to heavy-duty grinding, aluminum oxide's adaptability ensures that it's suitable for a wide range of applications. It's used in everything from the delicate polishing of optical lenses and semiconductor wafers to the heavy-duty grinding of automotive parts and aerospace components.

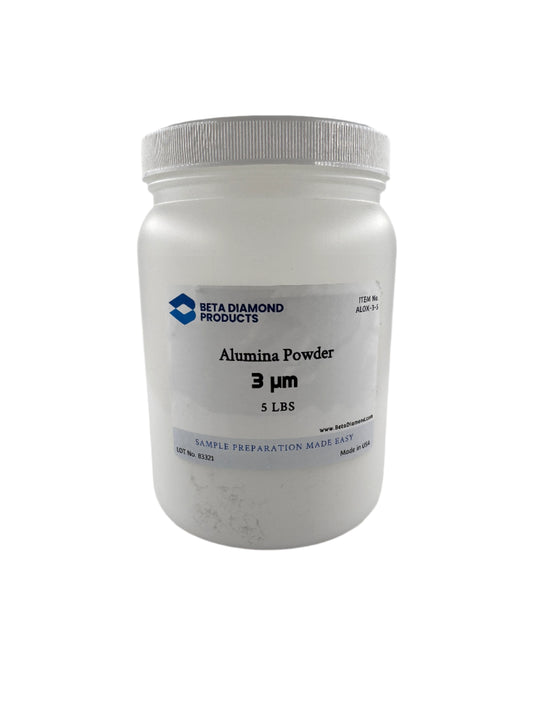

Choose Beta Diamond for the Best Aluminum Oxide Powder

Beta Diamond stands out as the go-to supplier for the best aluminum oxide powder. Our products are synonymous with reliability and quality, ensuring you get the best results in your applications. We provide a range of grades and sizes to suit various industrial needs, from precision polishing to heavy-duty grinding. Our commitment to customer satisfaction means you can count on us for consistent quality and expert support. Order your aluminum oxide powder today!

Shop NowOther Powdered Solutions

In addition to aluminum oxide powder, Beta Diamond offers powdered solutions catering to various industrial needs. These include:

- Diamond Powder: Known for its unparalleled hardness, diamond powder is used for high-precision polishing and grinding applications. It's ideal for use in the gemstone industry for polishing diamonds and other precious stones. Additionally, its thermal conductivity properties make it suitable for thermal management in electronics. Choose from natural, poly or synthetic diamond powder.

- Silicon Carbide Powder: This compound stands out for its exceptional thermal conductivity and electrical resistivity. Widely used in abrasive applications, silicon carbide powder is also a key material in manufacturing semiconductors and LED lights and is used in the production of ceramics and as a reinforcing agent in composite materials.

Frequently Asked Questions About Aluminum Oxide Powder

Aluminum oxide powder is widely used but often misunderstood. Let's address some of the common questions we've received:

What Are the Primary Uses of Aluminum Oxide Powders?

Aluminum oxide powders are predominantly used as an abrasive and polishing material, leveraging its exceptional hardness and strength. It's essential in manufacturing sandpaper, grinding wheels and cutting tools. Additionally, the powder finds application in the production of ceramics, enhancing stability and thermal properties. In the refractory industry, aluminum oxide powder is used in furnace linings and castables due to its high melting point and resistance to thermal shock.

Is Aluminum Oxide Abrasive Safe for Use in Medical Applications?

Absolutely. Aluminum oxide abrasive is renowned for its biocompatibility, making it a preferred material in medical applications. It's extensively used in orthopedic and dental implants because it bonds well with human bone tissue. Its hardness and wear resistance are also suitable for prosthetic devices and components in joint replacements.

How Does Aluminum Oxide Powder Perform in High-Temperature Environments?

Aluminum oxide powder exhibits outstanding thermal stability and resistance to high temperatures, often up to 2,000°C. This makes it valuable in applications such as thermal barrier coatings in jet engines and heat shields in space exploration vehicles. Its ability to withstand extreme heat without degrading is crucial in industries that operate under high-temperature conditions.

Can Aluminum Oxide Abrasives Be Used in Electronic Applications?

Definitely. In the semiconductor industry, aluminum oxide abrasives are valued for their excellent electrical insulation properties. They're employed in fabricating integrated circuit substrates and insulating layers and as a dielectric in capacitors. Their electrical insulation and thermal conductivity make them ideal for electronic packaging and thermal management solutions.

What Makes Aluminum Oxide Powder a Good Abrasive Material?

The extreme hardness and durability of aluminum oxide powder make it highly effective for abrasive applications. It's harder than most metals, allowing for efficient grinding, lapping and polishing of metallic and non-metallic materials. Its angular shape and high breaking point enable it to provide a consistent, high-quality finish in surface treatment processes.

Are There Environmental Concerns With Using Aluminum Oxide Abrasive?

Aluminum oxide abrasive is considered environmentally benign. Its chemical inertness means it doesn't react with other substances, reducing the risk of releasing harmful byproducts into the environment. Additionally, it's non-toxic, making it safe for use in various applications without posing significant environmental or health risks.